Contact Us

Contact Us

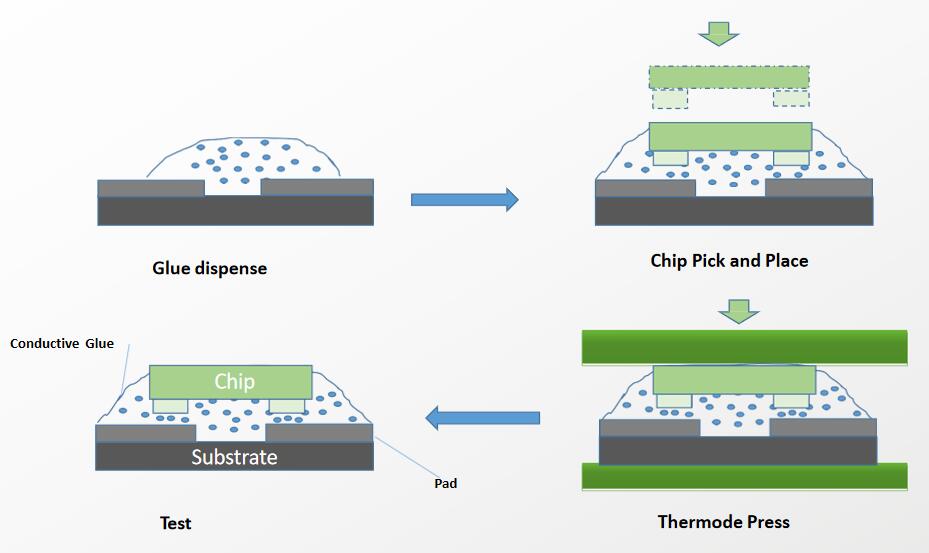

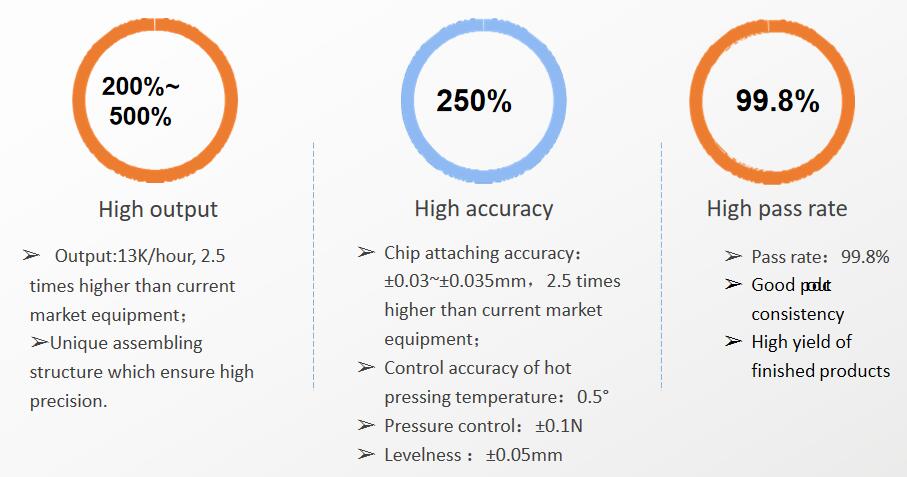

The inlay production system is the current benchmark and represents the most proven generation of Flip Chip RFID inlay production with a throughput of up to 15 000 inlays per hour. Flip chip on board technology is adopted to produce the RFID inlays, through high-precision modular mechanism, pick the chip from wafer, then place on pre-dispensing conductive glue with hot press, solidify wafer on the etched antenna, to conduct chip and substrate antenna, so that achieve RFID Inlay bonding. Precise vision system make sure accurately positioning and monitor the RFID chip and antenna bonding.

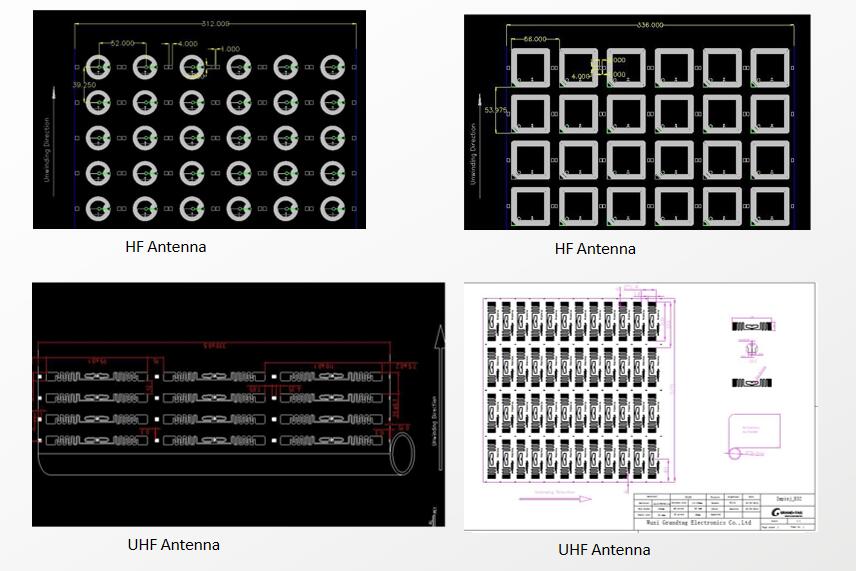

With the throughput in almost 99.7% yield, all of our processes are in one system platform which includes antenna web handling, epoxy jetting, flip chip, final curing, and testing. Available for all types of HF / UHF RFID Inlay.

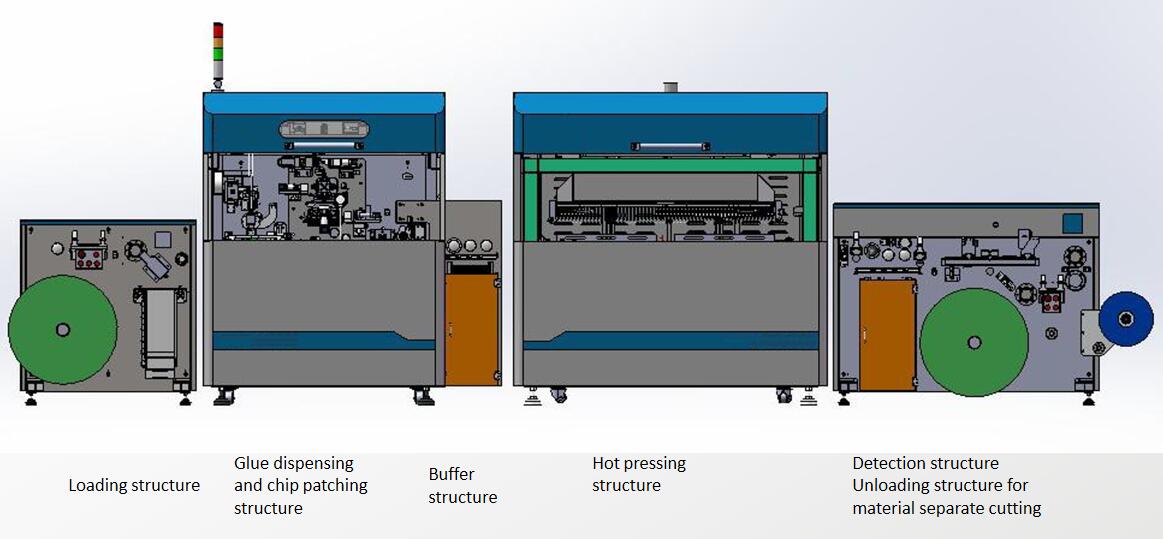

Working Station Overview:

Features:

■Designed for the RFID industry of IoT, electronic tag HF, UHF chip patch with high productivity.

■Suitable for the antenna with a wide width of 35-180mm,outer diameter of roll core of antenna is Max. 600mm.

■Fully autoamtic system with automatic antenna unloading, material pulling, glue dispensing, placement chip, hot pressing, detection mark and roll material loa

■Both 8-inch and 12-inch wafer plate are available,wafer attaching accuracy is ±0.035mm.

■Multiple sets of CCD vision localizationare are adopted to align the material& chip to meet the chip placement accuracy requirements.

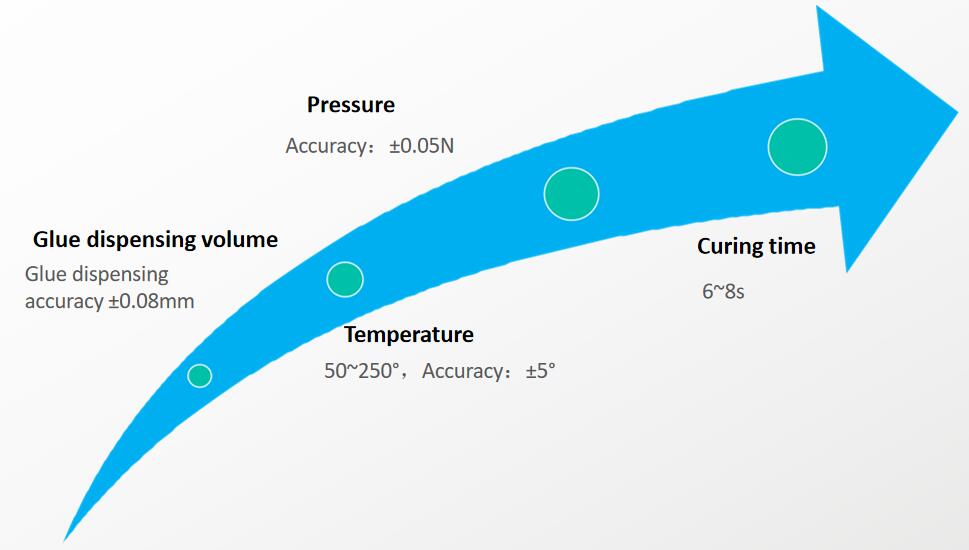

■The temperature range of up and down heating head is 50℃~250℃. Accuracy of temperature control is ±0.5℃, temperature can be calibration by software.

■With IPC control and international brand stepping motor, cylinder, guide rail & screw modular design for durable & stable performances.

■The unique hot-pressing design make sure each set of hot-pressing head flatness for the good quality of glue curing effect.

■Friendly HMI for easy operation Low standards for employees.

Technology Process:

Machine Advantages:

Specification:

| Model | LUK-DDA15000 | |

| Applicable Materials |

Water Disk Dimention |

8 inch or 12 inch |

| Chip Specification |

Chip dimension:0.2mm x 0.2mm~2mm x 2mm (can be customized); Chip dimension in common use:0.3*0.3~0.8*0.8mm; Chip thickness:0.075~0.15mm |

|

| Base Material for Antenna |

Base material: PET ; Thickness:0.035~0.2mm; Base width: 35-180mm (Max. 180mm) |

|

| Types of Glue |

Type of glue dispenser:Glue spraying type; Type of glue:Conductive glue(can use DELO AC265 or others) |

|

|

Jump pitch |

Min. 15mm |

|

|

Antenna width and antenna pitch |

Min. 0.2mm |

|

|

Inlay pitch |

X direction: Max: 100mm Min:20mm Y direction:Max: 180mm Min:35mm |

|

|

Glue dispensing accuracy |

±0.05mm |

|

|

Chip position accuracy before curing |

±0.03mm~0.035mm |

|

|

Chip position accuracy after curing |

±0.03mm~0.035mm |

|

|

ESD |

<±2KV |

|

|

Eye mark dimension(suggest) |

3*5mm |

|

|

Distance between square antenna to edge of film |

More than 5mm |

|

|

Visual system |

CCD visual system( Location vision、detection vision);(Germany VERMES) |

|

|

Controller & Power supply |

IPC ,380VAC |

|

|

Machine dimension |

L6600mm * W1600mm (Not include displayer)* H2000m |

|

|

Weight of machine |

4000KG |

|

| Productivity | 15000 UPH (Depend on different materials) | |

Process Parameter Optimization:

Products( Part of Samples Listed):

E-Mail : trade_2@lukiot.com

TEL: +86 17366051013 (7*24 Hours Support)

Add: Room 111, Building 5-2 Fortune Plaza, No. 228 Tianyuan East Road, Jiangning District, Nanjing City, China