Contact Us

Contact Us

Thanks to the modular platform of our converting line family, the CL-90W system is characterized by a successful combination of cost-efficient production and highest flexibility paired with the highest speed and perfect product quality. Smart labels, smart tickets, baggage tags, hangtags and wet inlays can be processed from reel-to-reel or reel-to-ticket. Due to its 100% output control the converting system is perfectly suitable for mid- and high volume production. To gain higher productivity the machine can operate in wide web application.

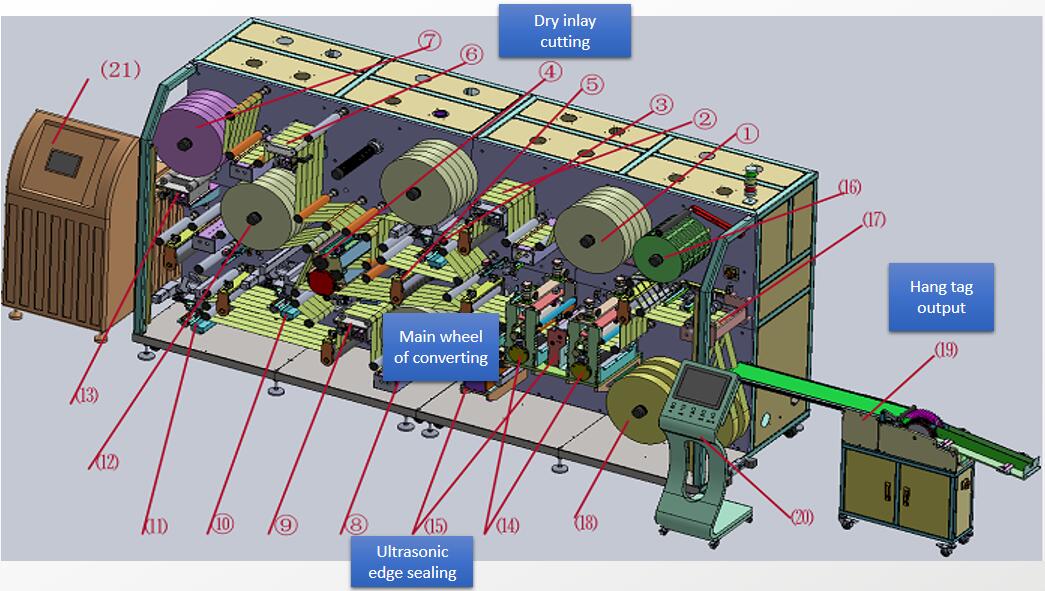

Function Module Description:

1) Printing layer loading 2) Printing layer correction 3) Printing layer gluing 4) Inlay cutting

5) Alignment and lamination 6) Correction 7) Inlay loading 8) Bottom layer loading

9) Bottom layer correction 10) Filled layer gluing 11) Bottom layer gluing 12) Filled layer loading

13) Filled layer correction 14) Die cutting A & B 15) Ultrasonic edge sealing 16) Discharge waste material

17) Roll material slitting 18) Rolling-up finished product 19)Hang tag output 20) HMI

21) Hot melt glue box

Main Configurations:

Features:

■Strong versatility, compatible with single-lane or multi-lane, reel label, hang tag, production;

■Simple operation, low requirements for employees, quick product switching;

■Friendly HMI interface, easy to operate and alarm automatic;

■Flexible machine, high compatibility, according to the need to compound 2-4 labels. Optional 0-3 groups of adhesive.

■Strong expansibility, optional chip quality detection function, vision system, cutting mechanism, die cutting and other functions

■Material collection can be optional reel label, hang tag.

■According to different product requirements, the material width, narrow range is optional.

■The machine has many emergency stop switches, which can be pressed to stop the machine in time in case of emergency.

■Single station independent test module, easy to adjust and replace;

■The machine is equipped with safety grating and protective cover, eu CE standard, to protect the safety of personnel

Specification:

Reel label:

same pitch:about 60~70m/min, different pitch:about 40~50m/min;

Hang tag:

same pitch:about 50m/min , different pitch:about 30~40m/min;

Woven label:

same pitch:about 60m/min different pitch:about 40~50m/min

Reel label:

same pitch:about 50m/min, different pitch:about30~40m/min;

Hang tag:

same pitch:about 40m/min, different pitch:about 30~40m/min;

Woven label(single lane):

same pitch:about 60m/min, different pitch:about 40~50m/min

Model

CM-90N(Narrow Web)

CM-90W ( Wide Web)

UPH

Lamination Layers

3

2~4 layers are optional

Width of material

30-150mm

30-350mm

Hot melt glue group

0~3 groups are optional

Double side adhesive tape

√

Unloading

Reel label、hang tag、fan fold card are optional

Liner

Optional

Dry inlay

Lamination directly or inlay cutting lamination(Standard)

Wet inlay

Optional

Bad/good detection

(HF/UHF)

Optional(The speed will be reduced to 15~30m/min)

Inkjet printing

Optional(The speed will be reduced to 15~30m/min)

Inlay rejected

Optional

Kiss cut/ full cut

√(Change the die cutting group, adjusting die cutting depth can be achieved)

Lamination accuracy

±0.5mm~0.8mm(According to different products and different production mode)

Die cut accuracy

±0.5mm~0.8mm(According to different products and different production mode)

Slitting

Optional

Application

Woven、baggage tag、reel label、hang tag、fan fold card

Application:

■ Ordinary paper of RFID lamination.

■ Hand-tag RFID lamination.

■ Care-label RFID lamination.

■ Dry inlay & wet inlay lamination.

■ Cutting function for dry inlay.

■ Finish paper and body paper automatically alignment laminated.

■ From the type of silicone oil body paper can be used as body paper.

■Double side adhesive label lamination.

■ Standard adhesive label lamination: Label body paper & finish paper split – laminating inlay- Three layers label lamination.

E-Mail : trade_2@lukiot.com

TEL: +86 17366051013 (7*24 Hours Support)

Add: Room 111, Building 5-2 Fortune Plaza, No. 228 Tianyuan East Road, Jiangning District, Nanjing City, China