Contact Us

Contact Us

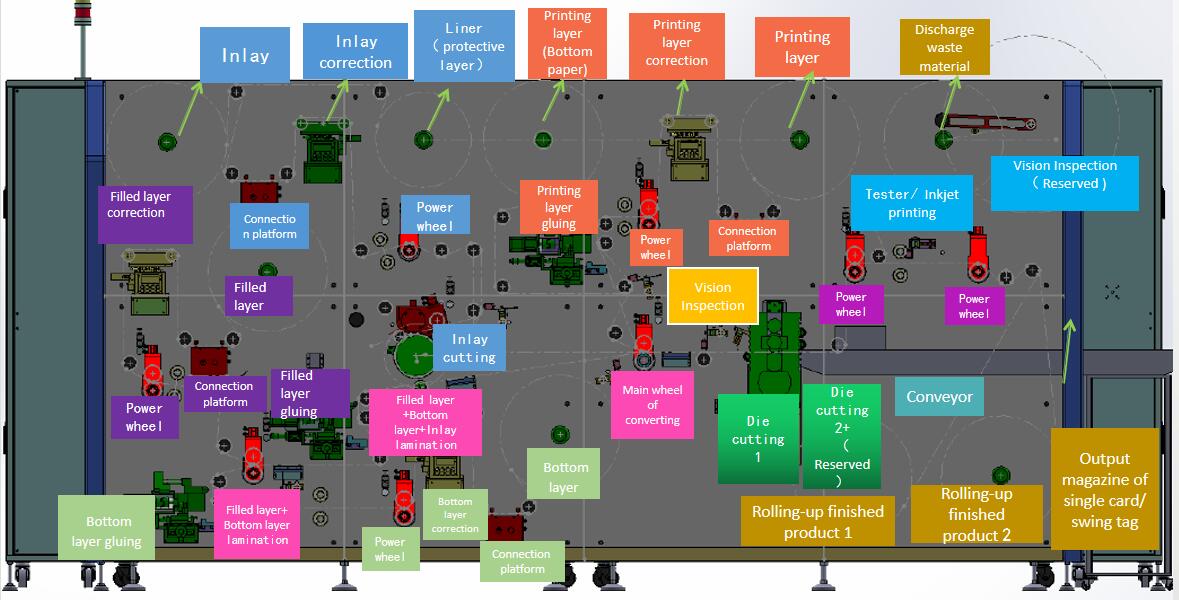

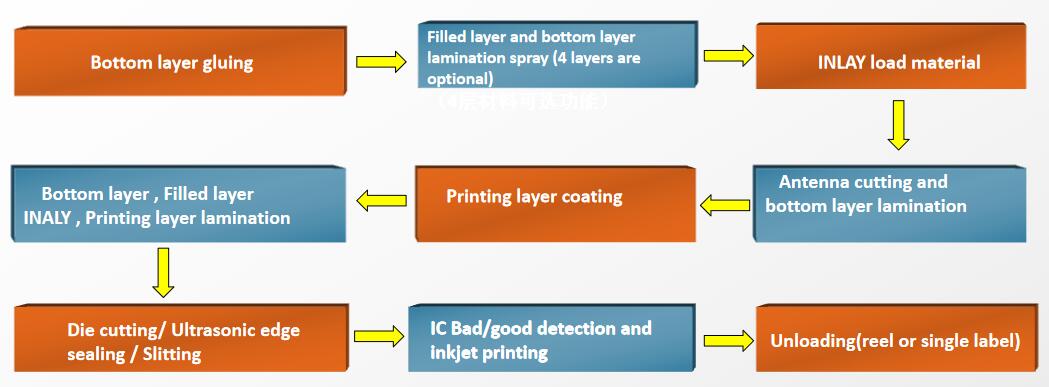

CM-90N Converting Line represents a flexible, fast and modular concept for a high range of converting possibilities: Smart Labels and Smart Tickets from reel-to-reel or from reel-to-ticket/fanfold. Various input materials like dry inlay, wet inlay and even compensation layers (4-layer) can be processed. All processes are in one platform: reel-to-reel antenna web handling, label/ticket lamination, die cutting as well as output testing – of course, with leading edge performance, state of the art quality and the best cost/performance ratio available on the market. It is perfectly suited for high-volume RFID Label and Ticket production, where the issues of fast change-over times and high quality are taken into account.

Working Process:

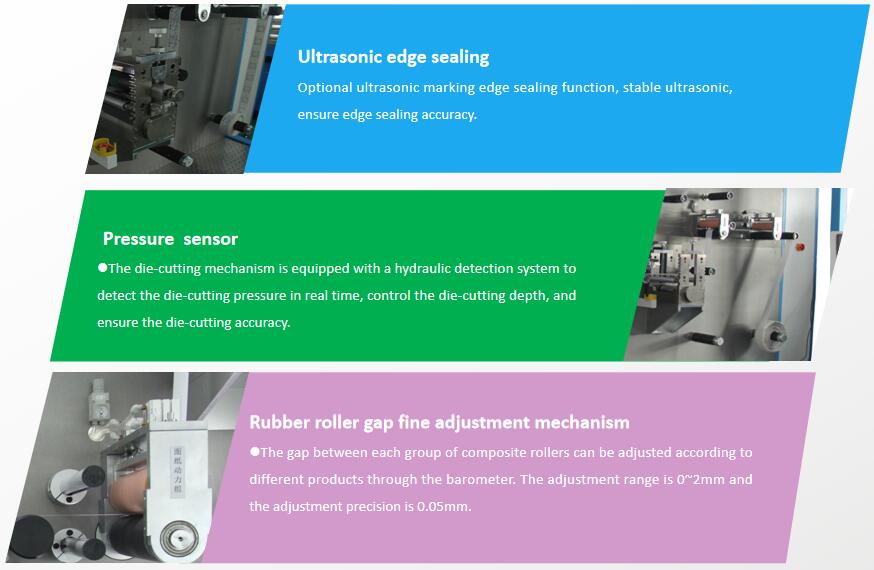

Fuctional Structure Description:

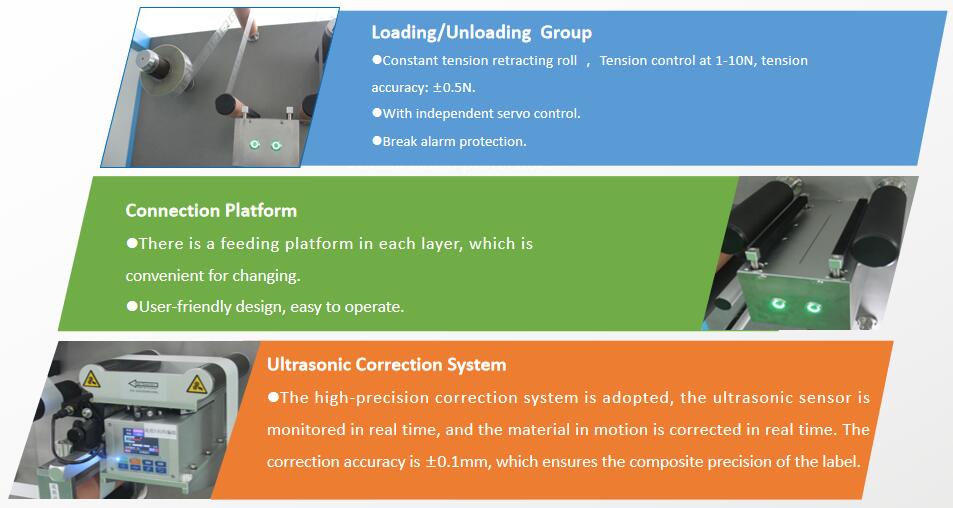

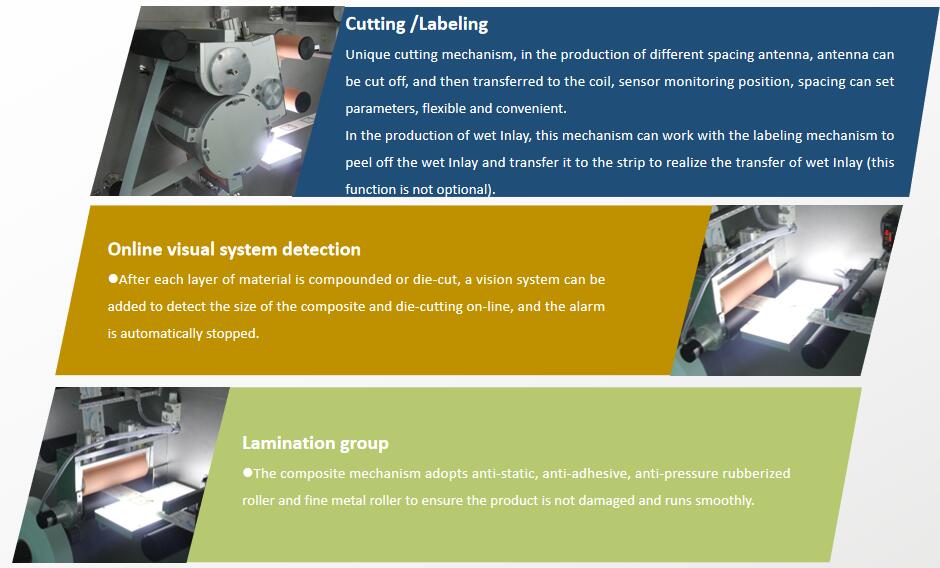

Features:

■Designed for label converting and die cutting, 2 layers or 4 layers of roll to roll dry and wet inlay converting with label is optional.

■Inlay converting and die cutting with balance or imbalance printing layer just need to setting in software.■Machine has multi unit of tension and deviation correction systems which ensure the edges neatly, high output, high quality and high accuracy production for different products.

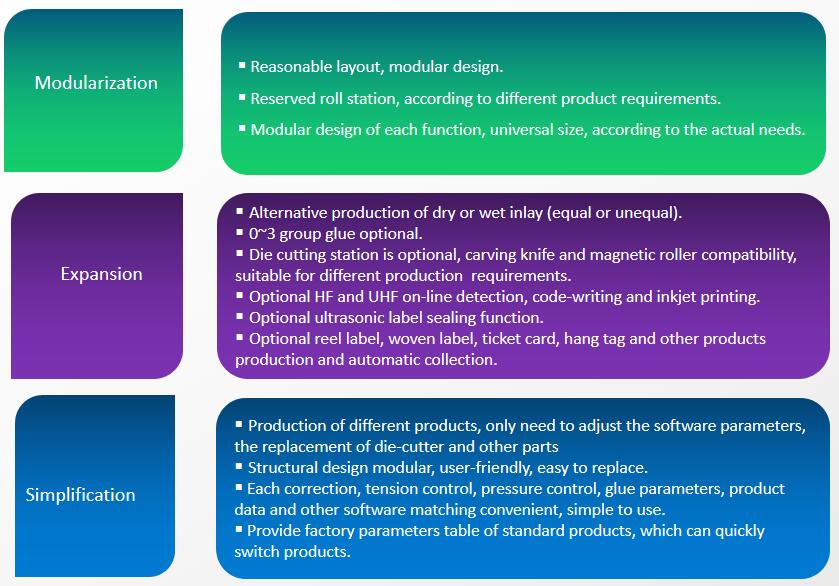

Advantages:

Specification:

| Model | LUK-CM-90N |

| Controlling System |

Bus control(Drive control integration) |

|

Width of Material (Label converting) |

20~180mm |

|

Application Materials |

Dry/wet inlay(different sizes) |

|

UPH |

Reel label:same pitch:about 60~70m/min ,different pitch:about 40~50m/min ; Hang tag:same pitch:about 40m/min ,different pitch:about 30~40m/min Baggage tag:about 30m/min ; Woven label:same pitch:about 60m/min , different pitch:about 40~50m/min |

|

Percent of pass |

about 99.7% |

|

Lamination accuracy |

±0.3mm~0.5mm(According to different products and different production mode) |

|

Die cutting accuracy |

±0.3mm~0.5mm(According to different products and different production mode) |

|

Capacity of hot melt glue machine |

35KG |

|

Max. diameter of roll material Max |

Max.600mm |

|

Air Pressure |

6KG/CM² |

|

Air consumption |

About 300L/MIN |

| Power Supply |

AC380V 50/60HZ 35KW |

|

Overall Dimension |

L4820*W1230*H2200mm |

| Net Weight |

About 2500kg |

| Slitting | Optional |

Applications:

E-Mail : trade_2@lukiot.com

TEL: +86 17366051013 (7*24 Hours Support)

Add: Room 111, Building 5-2 Fortune Plaza, No. 228 Tianyuan East Road, Jiangning District, Nanjing City, China